With a professional electromechanical R&D team and senior process and manufacturing management team, we can provide customers with full process collaborative services from design, manufacturing, assembly and testing.

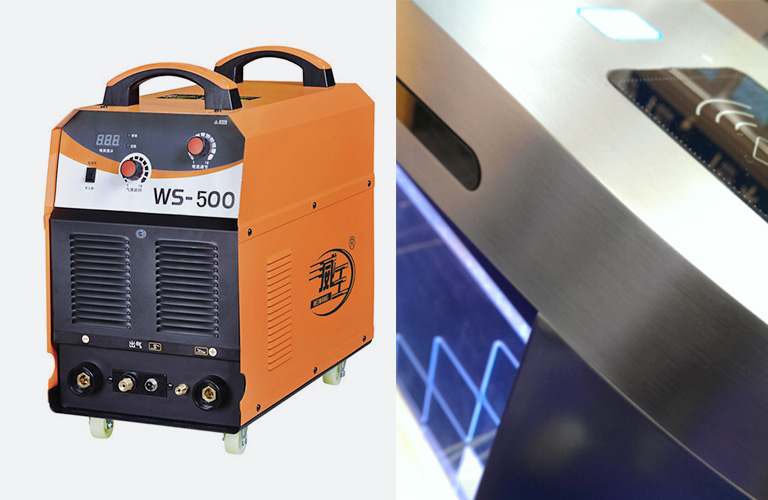

Suzhou and Danyang have a total of 5 advanced flexible sheet metal processing units, 3 laser cutting machines, 2 CNC punching machines, 10 CNC bending machines, several stamping and riveting equipment, more than 20 welding stations (gas welding, argon arc welding, laser welding) and welding robots, 200 hang /H automatic coating line (planning), the annual output value of sheet metal processing can reach more than 300 million yuan.

With the AI production scheduling system and efficient production execution system, it can effectively and efficiently ensure the supply needs of customers, and meet various urgent orders, replenishment orders and insertion situations. Achieve a minimum supply cycle of 3 days to help customers meet truly JIT and lean management. The on-time delivery rate of orders reaches over 99%.

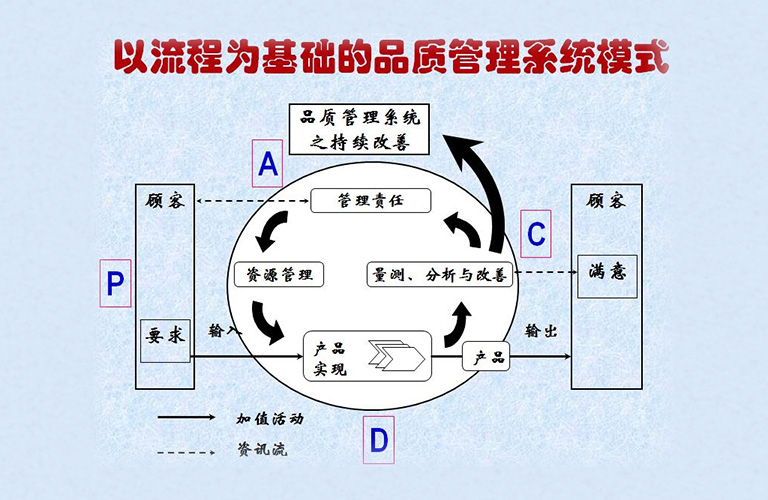

Advanced paperless process inspection system and quality tracking system ensure that product quality is recorded and traceable throughout the process. Factory pass rate > 99%, customer satisfaction > 98%.

Contact us

0511-86288862

wangll@sz-shinetek.com

︿